Magnetic bearing water cooled chillers, (available from 100 to 1500 tons); are designed to create the ultimate in climate-controlled environments for:

- Corporate offices

- Data centers

- K-12 schools

- University

- Hospitals

- Healthcare facilities

Magnetic bearing water cooled chillers, (available from 100 to 1500 tons); are designed to create the ultimate in climate-controlled environments for:

- Corporate offices

- Data centers

- K-12 schools

- University

- Hospitals

- Healthcare facilities

Building owners and property managers realise the benefits too, in terms of reliability and performance. And when it comes to saving energy, Magnetic Chillers are up to 40% more efficient than standard centrifugal chillers and can save up to $4 million over the life of the chiller.

Service and Maintenance Savings

Because the Magnetic bearing chillers has fewer moving parts they require no oil, nor oil-circulation equipment, it therefore requires less maintenance and service. Over the life of the equipment – approximately 20 to 25 years – the total maintenance savings could be significant.

Our Bottom Line For Your Bottom Line – Contact Frigcorp Building Technologies for more information or to organise a quote for the installation of a state of the art Magnetic Bearing Chiller in your building.

Ideal for Retrofit and Replacement

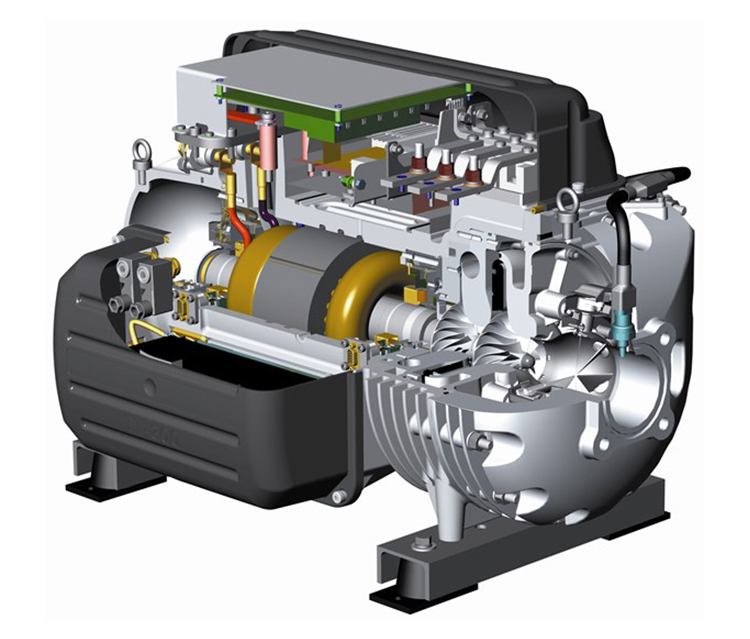

The compact size of the Magnitude chiller makes it ideal for retrofit and replacement installations. Most models can easily fit through double width doors without any disassembly

Service and Maintenance Savings

Magnetic bearing compressors were developed to improve performance, reliability and reduce service requirements as compared with conventional centrifugal compressor designs.

Magnetic bearing design eliminates mechanical seals, wear surfaces, gears and slide valves for longer machine life and increased reliability.

Oil free Design

An Oil-free design eliminates oil management systems for improved compressor and system reliability. The oil-free design also eliminates the possibility of efficiency-robbing oil contamination of heat-transfer surfaces.